Chun glaze

Have had a rather busy few days, but managed to get some more glaze testing done. I was pleased with this little bowl, it went in with the glaze test firing. There are three glazes used in all, and most of the colour comes from light being scattered within the glaze. I was pleased to see colours that ranged from violet through blue to pale green.

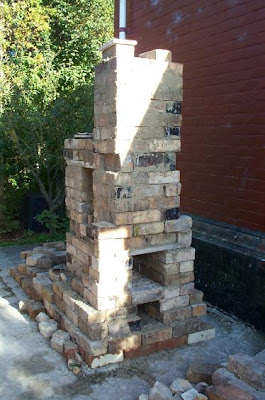

Have had a rather busy few days, but managed to get some more glaze testing done. I was pleased with this little bowl, it went in with the glaze test firing. There are three glazes used in all, and most of the colour comes from light being scattered within the glaze. I was pleased to see colours that ranged from violet through blue to pale green. Very tired at the moment, so I am keeping this brief. I am sorting through photos of kilns that I have built, and will post them on this site quite soon. It is quite fun looking back at the progression from the first wood fired kiln, that had a chamber of only about 1 cubic foot, through to the one I use now; and the photos might prove helpful to someone else one day, who knows!

Comments

There are three glazes on the pot that are put on one after the other in layers. The first one to go on is a temmoku glaze, then there is a clear glaze that I modified by adding about 3 percent rutile and one percent of copper in it, and on top of that is a chun (jun) glaze. I can post the recipe some time, but am just about to race out the door now to catch a bus.

Nice to here from you. Best Wishes.

Thank you

Teresa

I would love to be able to help with a recipe for you, but I haven't done a lot of cone six firings, so I'm probably not the best one to ask. I use an Emmanuel Cooper chun recipe quite a lot, which I usually fire between cone 9 and cone 10. This recipe is really supposed to be for Cones 7 - 9 and I was wondering if you could adapt it to cone 6 by adding some borax frit, probably 10 - 20 percent??

The recipe is as follows

Potash Feldspar 46

Dolomite 6

Zinc Oxide 6

Whiting 10

China Clay 2

Silica 30

I find this gives a good blue chun when used over an iron bearing slip or a tenmoko type glaze. Reduction is not needed for this glaze, and I have good results in an electric kiln. It does seem important in oxidation to use an iron bearing slip or glaze under the chun for the best results. Probably less important in reduction where iron is being drawn through the glaze from the body of the pot.

June Perry of Shambhala pottery has some interesting looking cone 6 glazes on her main web site http://www.shambhalapottery.com/technicallinks.html

It might be worth leaving a question on her blog http://shambhalapottery.blogspot.com/

Good luck with it, P.

-Bethany

Sorry not to get back to you sooner, I should check my mailbox more often! I see that you made about 3 attempts to get in touch with me.

Thanks for your interest in the glaze, I am really happy to pass on recipes and other technical stuff.

Chūn glaze (Emanuel Cooper recipe) Really for cone 8-9, but I fire 10 – 11 with this glaze.

Potash Feldspar 46

Dolomite 6

Zinc Oxide 6

Whiting 10

China Clay 2

Silica 30

Bentonite 1

This works well for me over a variety of tenmoko glazes or iron bearing slips.

One cone 10 glaze that works well under the Chūn glaze shown above is as follows, (I think this is the one I used on the bowl in the photo you saw),

Silica 41

Potash Feldspar 34

Whiting 16

China Clay 9

Black Iron Oxide 10

I usually pour my glazes, or dip a pot in the glaze bucket, and a certain amount of unevenness is a good thing for these glazes, as it gives a more interesting range of colour. I apply the under-glaze, then usually apply the Chūn glaze over the top as soon as the first glaze is only just touch dry. It does depend on how thick your pots are as to how well they will take more than one application of glaze. Really thin pots get too saturated with water from the first glaze, and you have to wait for them to dry before the next glaze will go on. Probably you could have a lot of success with spraying the Chūn glaze over the under-glaze.

It is worth experimenting with all sorts of under-glazes. I find it does make a real difference as to how the Chūn glaze performs. I have even used them with success over copper red.

I wrote a fairly detailed response to someone recently who asked about my Chūn glazes. I replied to her question on

http://opopots.blogspot.com/2009/01/about-tiles-and-glazes-by-peter-gregory.html

and I have left a couple more recipes there too. Another, more difficult (but rewarding) Chūn glaze, and another under-glaze that is quite reliable.

Good luck with it. Do let me know how you get on.

Any tips or tricks that might help me on my quest would be appreciated.

Welcome to my site. Sadly I am not able to help you with this as I have no experience of cone 5 glazes (or salt firing). Wood ash certainly can be helpful in making chun type glazes, as can small amounts of rutile, or bone ash, or zinc.

Hopefully another potter reading this might be able to add some helpful advice regarding chun type glazes for cone 5.

If you do manage to find something that works for you, do post a comment here and let us know, it might help someone else who is working in a similar temperature range.

Best of luck, P.

Thank you for letting us know, I am very pleased to hear that the glazes worked so well for you and that you were able to convert them to cone 6. Did you take any photos? I would be very happy to post some on this site and the modified recipes that you used as I know that there are others who would love to do chun at cone 6, and it could be very helpful. Anyway, well done for experimenting and modifying the glaze to fit your requirements. Good to hear from you.

Best Wishes, P.

Just found your blog and I am overwhelmed with your generous sharing of recipes and information. I am a bit of a part time potter because I am a full time art teacher. I feel like my lack of interesting results with glazing (electric kiln) is partly what prevents me from going further with it.

Just wondering:

1. What type of clay do you throw with to get that beautiful chun/tenmoku combo?

2. How thin are your glazes to get them to layer without cracking and falling off while drying?

3. Do you fully dip in tenmoku then fully dip in chun?

Thanks for the help and the inspiration.

Kind regards, Sarah

Just found your blog and I am overwhelmed with your generous sharing of recipes and information. I am a bit of a part time potter because I am a full time art teacher. I feel like my lack of interesting results with glazing (electric kiln) is partly what prevents me from going further with it.

Just wondering:

1. What type of clay do you throw with to get that beautiful chun/tenmoku combo?

2. How thin are your glazes to get them to layer without cracking and falling off while drying?

3. Do you fully dip in tenmoku then fully dip in chun?

Thanks for the help and the inspiration.

Kind regards, Sarah

Hi Sarah,

Lovely to hear from you, thanks for your kind words, & welcome to my site.

Sorry that it has been a couple of days replying to your comment, the whole Blog system went down and it was impossible for me to post a comment. I also notice that your comment got removed in Blogger's world wide hiccup, but I fortunately had already grabbed a copy before it vanished so have included it above my reply!

You don't say if you are in New Zealand or in another part of the world, so I am not sure if you are able to access the same clay as me, but.. I have been mostly using Southstone, which is made by Southern Clays Ltd in Dunedin NZ. Southstone is a rather sandy, open clay, and is a bit problematic in an electric kiln as it needs a lot of heat to vitrify. I use it, because it is my local clay and I like to support Southern Clays as much as I can. One trick that I do with it that will lower its maturing temperature, is to wedge in a little earthenware clay (Southern Clays Brick Red works nicely). I find that 4 parts Southstone to one part Brick Red gives me something that will be mature at cone 9 or 10, and it also has a better colour in an oxidized firing.

Southstone does contain a bit of iron oxide, and this is helpful when trying chun glazes. It is far harder to get chun glazes working on a white stoneware body. Having said that..., it is possible. I have tried the tenmoko/chun combination over a white slip, and this can work, but an clay that has some iron is an easier starting point.

I put on my glazes as thickly as I can for the chun/tenmoko combo. They do tend to crack as they dry, and I give them a gentle rub with my fingers to "heal" them over. Occasionally the glaze may crack and lift. I carefully moisten the lifted edge with a little water applied with a small paint brush, then push it down again.

I do often dip the tenmoko glaze (but have been known to pour it or brush it). I mostly pour the chun glaze for the inside of a bowl, swirl it around, and tip it out again. Brushing is impossible with that glaze. I quite like the glaze to be uneven, so I have never sprayed it, but I imagine that this would work OK.

Hope that is of some help. It is difficult to talk about glaze thickness and so on, as it really is something that you need to experiment with with your clay and glazes... there are so many variables. I should add that I bisque to 1000 Centigrade (Southern Clays suggests 1050 C), as I quite like my bisque to be reasonably absorbent. Do keep in touch and feel free to ask questions.

Best Wishes,

Peter

Thank you for your question. I have never had this glaze tested, but I am confident that it is safe. The materials used are all none toxic apart for the 6 percent Zinc Oxide. I doubt very much if the Zinc would leach out as this is a nice, vitrified, mature glaze.

Best Wishes, Peter.

jean from belgium

The blue chun effect is best achieved by using two glazes, an almost clear one over one that is very dark.

The "clear glaze" part of the chun is as follows:

Potash Feldspar 46

Dolomite 6

Zinc Oxide 6

Whiting 10

China Clay 2

Silica 30

(I usually add 1-2 percent bentonite to this to make it easier to apply).

This glaze is put over an iron bearing glaze and will form a blue chun effect if put over an iron bearing glaze or slip. On its own it is a slightly milky to clear glaze, becoming more clear towards cone 9.

A suitable iron bearing glaze would be:

Silica 41

Potash Feldspar 34

Whiting 16

China Clay 9

Black Iron Oxide 10

Many other glazes with about this level of red or black iron oxide will do just as well, it is worth experimenting.

The combination of glazes that I have given you here work for me between about cone 9 and cone 11.

Whilst I have mostly found this a very reliable glaze combination, I have had some problems with it recently after I purchased a finer ground zinc oxide, I suspect this is too effective as a flux. I am still working through this.

Hope the information helps. Good luck! P

Thank you for your question, I would like to be able to help, but I am struggling to find the blog post that you refer to (where I refer to needing to catch a bus), could you give me the date of the post, and then I can help you more regarding the glaze question. P.

Really sorry for the muddle about the glaze. Here it is. This cone 9 glaze is really a Janet DeBoos one, number 144 from her book "Glazes for Australian Potters".

I never found the original recipe much good, it did not yield the "smooth, white glaze" that she described, and it often seemed to craze on the clay I used. At some stage I tried it as a base and added other things, then found it very useful.

Her glaze is as follows:

Potash Feldspar 40

Silica 200 25

Calcite 15

Ball Clay 10

Zinc Oxide (dense) 5

To this I add Bentonite 2

Copper Carbonate 1

Rutile 3

In an electric kiln, this will probably give you a green, but it can also give a lovely variety of blues right through to a deep blue/purple in reduction. The glaze is quite like a chun in effect, and I will sometimes use it along with a chun glaze for variety, under, or over the chun glaze. I apply it in an informal, spontaneous way. It is useful for this, both in oxidized or reduced firings.

(I have also posted this comment on the chun glaze post).

Good luck with your own experiments with these glazes.

The "middle glaze" (the DeBoos 144) isn't strictly necessary for the blues, but can make them more interesting. I think that your three layer description is probably a bit too "formal".. Yes, the tenmoku goes first, but what is done over that is more instinctive. I suspect that, in the case of the blue bowl on this post, the next glaze to be applied would have been the chun, and the adapted DeBoos added by pouring in and out quickly, more as a splash then as a complete coat. Hope all that makes sense!

Really it is the sort of thing that is hard to describe as a "method", as I mostly end up in a state of creative chaos when I am glazing, surrounded by a growing number containers of glaze, and am inclined to splash in a bit of this and that, as the "spirit moves"!

I'l definitely be playing around with this glaze, I'm going to try mike's suggestion of .25 lith carb and 10 custer feldspar for cone 6 oxidation firing. I'll keep you posted on how it goes.

The heavy iron dark clay body would be ideal. Chun blues are much easier to do with a dark background. I think that the theory is that the dark background absorbs the other colours of the spectrum, but the chun reflects back blue light to the viewer. Without the dark background, the other colours of the spectrum reflect back, and you lose the blue chun effect. Definitely test, and re test... Sadly, the other potter hasn't got back to me. It would be very interesting to see photos of work that has been done at cone 6 with an adaptation of this glaze.

I am trying to make an underglaze for some chun glazes and was wondering if you had a recipe for an underglaze at cone 10?

You can use chun over all all sorts of other glazes and it is well worth experimenting, for example... I have used them over copper reds, and shino.

However, you will usually get a good result over a tenmoko (temmoko) style glaze, as a really dark, almost black, glaze will absorb the unwanted light spectrum, and leave your chun glaze to reflect back to you the blue wavelengths.. thus you should see a nice optical blue colour if all works according to plan!

This cone 10 glaze works well as an underglaze for chun, and you should find it a good one to start with:

Silica 41

Potash Feldspar 34

Whiting 16

China Clay 9

Black Iron Oxide 10

Note... If you under fire a chun glaze, you will usually end up with a milky white; and if you over fire a chun glaze you will end up with a clear glaze that just shows the dark under glaze without giving you blue.

Best Wishes, P

No question but would like to thank you for all the above advice. I am soon to move from earthenware to stoneware and wanted a couple of glazes to start/experiment with and thanks to this I think I know what to pick!

I do have a question after all. I am firing in an electric kiln and note you said:

"I find this gives a good blue chun when used over an iron bearing slip or a tenmoko type glaze. Reduction is not needed for this glaze, and I have good results in an electric kiln. It does seem important in oxidation to use an iron bearing slip or glaze under the chun for the best results."

When you say you have had good results in oxidation do you mean you have had results similar to the bowls pictured above?

Also what should I expect to get from the tenmoku recipe you gave above? Will I be able to get the black in oxidation?

Thanks again,

Daniel

The bowls in the photo were fired in my electric kiln in oxidation, and the black tenmoku is usually fired in my electric kiln as well, and can give a good very dark brown-black colour. To get the best black it is important to fire from cones 8 to 10 slowly, this glaze likes heat and time!

The blue chun can be fired slightly lower, it should work from cone 9 upward. I used to have a lot of success with the chun, and then couldn't get it to work at all for a couple of years. The problem I think was caused by a particular batch of zinc oxide that I was using, and unfortunately I had bought a 25 KG bag of it which took me a long time to use up! Now that it is gone, I am able to get the blue working again! Glazes can be tricky, particularly those that rely on layering one glaze over another. Don't give up if you find things don't work as expected the first time!

Do use cones when you fire, they are really the only way to accurately compare one firing with another.

Best Wishes, P

Thank you so much for that. Really excited to try this out! I am actually in the process of changing from earthenware to stoneware and plan to fire >cone 9. I haven't decided on a clay body as of yet. Will a higher iron content clay make a difference in oxidation? Do you think I should stay clear of a white stoneware body for the sake of glaze interest?

Also, have you had any interesting variation in the chun colour over a different glaze? Reading about oil spot effects using high iron content made me wonder: has any one managed to get that effect and the blue from the chun? Perhaps the micro bubbles necessary for the blue chun and the bubbling that causes the oil spots are incompatible. Just thinking out loud.

Thanks again

Daniel

It is worth experimenting with clay body. There is nothing "wrong" with white stoneware, or with stoneware with a higher iron content, but the two make possible different things. I like some of my cobalt blue glazes better on a low iron stoneware, but appreciate the extra complexity that a higher iron body will give to my green glazes. When it comes to chun, you are most likely to get them to work on a body that has some iron in it.

I sometimes mix a brick red earthenware clay into my stoneware clay for when I fire in the electric kiln. The brick red clay lowers the maturing temperature of my high fired stoneware body, and also gives the clay a warmer "toasty" look.

I have experimented with the chun over other glazes, and it is certainly worth experimenting. When firing in my wood fired kiln I have used chun over copper red and shino glazes with some success.

If you are firing to cone 9 you will probably find the Black Tenmoku glaze that I have here a bit under done, but the Red Tenmoku recipe that is on my High Fire Glaze page should work OK (the "red" gives a dark tenmoku brown with an iron red "break" where thin over some clays).

Red Tenmoku cone 9-10

Potash Feldspar 50

China Clay 10

Whiting 5

Dolomite 15

Silica 30

Red Iron Oxide 8

Good Luck! P

Can I ask how thickly you apply the chun glaze? And have you found the normal cool down of your kiln is fine?

Daniel

Normal cool down in my electric kiln has been fine for chun. Glaze thickness is an interesting one.... The chun really has to be applied over another glaze, such as a tenmoku for it to give a good blue. I first apply the tenmoku, and have the chun ready and waiting to apply as soon as the tenmoku is just about touch dry (no shiny bits anywhere). Then I quickly apply the chun by pouring it. The timing of this is important, if the tenmoku is too dry it may blister and pop off the pot, and if it is too wet it won't accept the chun. You will find it fairly easy to apply if you pour quickly and don't fuss with it. If you go back over an area it may well blister and start to lift off the tenmoku glaze.

You may find that the chun cracks a lot as it dries over the tenmoku, or even starts to lift in places. Usually this is not harmful and it will heal when fired, but if it is lifting badly I dampen the edge of the lifting part with a small wet brush, and it will sit down again!

I guess that the chun could also be applied by spraying, and this might make the application easier?.. but I haven't tried this myself!

Try on something that doesn't matter, glaze application is a bit of a conjuring trick, and needs practice!

Best Wishes, P

Thanks for that. Really useful information. Might be a while before I get the chance to try this but will post results when I do.

Best wishes Daniel

I have finally got around to testing the your Red Tenmoku and Chun recipes with some promising results. I managed to get some of the blue effect with chun over tenmoku and much more pronounced on a darker clay. I also tested the chun on its own. It was transparent with a thin application but in the thicker parts there were bubbles giving a violet colour.

I fired to 1270 Celsius in my electric kiln with no soak which saw cone 9 fully bent and cone 10 just starting to bend.

Is there a way to post pictures here so I can show you?

best wishes, Daniel

Good to hear from you, and that the results are looking promising. Glad that you have got some of the blue showing.

I would love to see some photos.. :-)

The best way is to email me at opogallery AT gmail DOT com (with the necessary alterations to make it a proper email address!).

Must dash now as am due out in about 1.5 minutes!

Looking forward to your Email,

Peter

Good to hear from you, thank you for stopping by this blog. The firing for this glaze combination was usually cone 9 to cone 10 in oxidation in an electric kiln. This works best on a buff stoneware body that contains some iron. A white stoneware is never as successful.

I don't know if you are writing from New Zealand or another country, but the stoneware body that I generally use is Southstone from Southern Clays in Dunedin NZ, but I sometimes add a quantity of brick red earthenware clay to give it a better colour when fired in oxidation and to drop its maturing temperature. Southstone on its own really wants cone 11 in reduction to be vitrified and water tight.

Thank you for your generosity in sharing your glazing techniques , recipes etc. I find glazing a bit of a challenge so always looking for inspiration and you have provided plenty! All the best and keep warm!

Cheers Monique (Rangiora, NZ)

The addition of bentonite will have been an attempt to make the glaze behave a little better in the glaze bucket, or when stored. The addition of a small amount of bentonite will often improve glazes quite a bit as far as their storage and application goes, without noticeably affecting their fired appearance.

Best Wishes,

Peter

I popped back to see whether you'd left a new post on how your beautiful crystalline pots went at the show - really well I hope. I also hope that your health held up after the mad rush to get everything ready.

I was also wanting to ask whether you had a chun-type glaze which fired in oxidation at 1280ish, but after a trawl through your glaze posts I found the Emanuel Cooper, which looks perfect.

What struck me yet again was your generosity and patience - often repeating the recipe for the same glaze lower in the comments, giving everyone individual attention. I award you the badge of Beeskneesness! (if, indeed, it is mine to award).

Hope all is well and that Summer is shaping up there.

Hope the Emanuel Cooper glaze works for you. It is certainly worth a try. I found it reliable for a number of years until I changed to another source of supply for my zinc oxide, and then it tended to give a clear rather than blue chun result.

Happy New Year to you.

Thank you for your lovely comment on my rather neglected blog! I'm glad that you have been enjoying reading it. Wales doesn't seem so far away really, I still remember some lovely family holidays that we had in Wales when I was a child (many, many years ago!!), and it is a magical place. I do know that you have some very fine potters in Wales. I have been meaning for ages to put another blog post together, and you never know.... you may have inspired me to dust down my keyboard! You are welcome to email me with some photos, if you peer around the blog you should find a "Contact" page with an email address.

Best Wishes for 2022.

Peter

I had very good results with your red tenmoku which turned out black! This I fired under the nuka. Lovely trailing effects. Thank you so much for continuing to answer posts and share such a wealth of information. I will let you know how I get on. You are a real inspiration to me💗

"Chaotic" glazing is often the way it ends up for me! I'm currently glazing some stoneware pots to go in the wood fired kiln, and I have found a few that I glazed a year ago, but never got round to firing, that will go in this kiln load too.... trouble is, after all this time, I really don't know what some of the glazes will be, so the firing will have some surprises!

Glad that you are having some good results with RTM, and it is interesting to use such glazes under others. It has been a long time since I really updated the blog, but I am hoping to post more regularly again, and may even get round to adding a few more glazes to the high fired glaze page at some point. Unfortunately I'm not sure how to contact the Welsh "spontaneous glaze splasher", but you never know, you may meet up one day...

Do let me know how you get on with the glazing.